Jingdezhen Ancient Kiln Folk Customs Expo Area

1. Introduction

The Jingdezhen Ancient Kiln Folk Customs Expo Area is located at Panlonggang, Fengshushan, Changjiang District, Jingdezhen City, Jiangxi Province. Covering an area of 83 hectares, it is a cultural tourism scenic spot integrating cultural exhibition, ceramic experience, and entertainment leisure. It is the only national-level tourist attraction in China themed on ceramic culture. The main scenic spots of the Jingdezhen Ancient Kiln Folk Customs Expo Area include three major areas: the Exhibition Area of Ancient Kilns from Various Dynasties, the Ceramic Folk Customs Exhibition Area, and the Waterfront Qianjie Creative Leisure Area. In April 2013, the Jingdezhen Ancient Kiln Folk Customs Expo Area was awarded the honorary title of "National AAAAA Tourist Attraction."

2. Geographical Environment

2.1 Location

The Jingdezhen Ancient Kiln Folk Customs Expo Area is located at No. 1 Guyao Road, Cidu Avenue, Panlonggang, Fengshushan, Changjiang District, Jingdezhen City, covering an area of 83 hectares. It is adjacent to Jingdezhen University and Yilong Hotel.

2.2 Production Environment

Jingdezhen is located in a hilly region, situated in the transitional zone between the Huangshan and Huaiyu Mountain ranges and the Poyang Lake Plain, making it a typical red soil hilly area of southern China. The average altitude within the urban area is 32 meters, with the terrain sloping from northeast to southwest. The northeastern and northwestern parts are mountainous, with the highest peak located at the provincial border adjacent to Xiuning, Anhui, with an altitude of 1,618 meters. Jingdezhen has a subtropical monsoon climate, characterized by abundant sunlight, ample rainfall, mild humidity, and distinct seasons. The main mineral resources include porcelain stone, kaolin, coal, tungsten, placer gold, copper, fluorite, sulfur, limestone, marble, etc., with porcelain stone, kaolin, and coal being particularly distinctive. Jingdezhen's kaolin has an international influence in the ceramic world. Kaolin is the most important raw material in the ceramic industry. The kaolin produced in Jingdezhen is of very high quality, and the porcelain made from it once represented the high-end level and superior quality of Chinese ceramic products, influencing China and even the world. The internationally accepted scientific name for kaolin—Kaolin—originates from Gaoling Mountain near Gaoling Village, Ehu Town, in the northern mountainous area of Jingdezhen.

3. Main Attractions

3.1 Bronze Statue of Kiln God Tong Bin

Tong Bin is the kiln god worshipped by Jingdezhen's ceramic industry workers throughout history, also known as the "Wind and Fire Immortal Master." The bronze statue of Kiln God Tong Bin is 9.9 meters tall, with a total height of 15.9 meters. Its image interprets the dedication and immense contributions of Jingdezhen's ceramic industry workers over the centuries.

3.2 Zhimeixuan Ceramic Exhibition Hall

The exhibition hall is divided into seven major exhibition areas of ceramic cultural knowledge, allowing visitors to experience a clear development lineage of ceramics and gain rich historical and cultural knowledge.

3.3 Yuan Dynasty Mantou Kiln

The Mantou Kiln is one of the typical porcelain kilns used in Jingdezhen during the Song, Yuan, and Ming dynasties, named for its resemblance to a steamed bun (mantou). Some Mantou Kilns have a horseshoe-shaped kiln bed, hence also called horseshoe-shaped kilns. The Mantou Kiln is a semi-downdraft kiln, where flames shoot from the fire chamber to the kiln top and then downdraft to the kiln bed, with smoke discharged through the flue outlet, vertical flue, and chimney. The firing temperature of a Mantou Kiln can reach up to 1,300 degrees Celsius and can create a reducing atmosphere.

3.4 Song Dynasty Dragon Kiln

The Dragon Kiln is one of China's traditional ceramic kilns, built leaning against a hillside and named for its dragon-like shape. The Dragon Kiln has a simple structure, divided into three parts: the kiln head, kiln bed, and kiln tail. It typically uses grass, branches, etc., as fuel. It is low-cost, has a large loading capacity, and can fully utilize waste heat. Built using natural slopes, it has strong flame draft and can create a reducing atmosphere suitable for firing celadon and Yingqing porcelain. The Dragon Kiln made outstanding contributions to the prosperity of Jingdezhen's ceramic industry during the Song Dynasty. Remains of Song Dynasty Dragon Kilns have been discovered in multiple locations in Jingdezhen, such as Hutian, Yaoli, and Liyang.

3.5 Ming Dynasty Gourd Kiln

The Gourd Kiln is the abbreviated name for the gourd-shaped wood-fired porcelain kiln in Jingdezhen. The Gourd Kiln is unique to Jingdezhen, first appearing in the late Yuan and early Ming dynasties and gradually falling out of use after the emergence of the egg-shaped kiln (Zhen Kiln) in the early Qing Dynasty. Ming Dynasty scholar Song Yingxing's "Tiangong Kaiwu" contains specialized textual records and illustrations of Jingdezhen's Gourd Kiln. The Ming Dynasty Gourd Kiln combined the advantages of the Dragon Kiln from the Song and Yuan periods and the Mantou Kiln, making significant progress in firing techniques and contributing greatly to the development of Jingdezhen's porcelain industry during the Ming Dynasty and the formation of the Qing Dynasty Zhen Kiln.

3.6 Qing Dynasty Zhen Kiln

The Qing Dynasty Zhen Kiln (abbreviated as "Zhen Kiln") is a uniquely styled porcelain kiln among China's traditional kilns. The kiln house is a post-and-lintel wooden structure building. It is 15-20 meters long, with a volume of about 300 cubic meters and a maximum height of around 6 meters. It uses pine wood as fuel for firing (hence also called "Chai Kiln" or "Wood Kiln"), producing long flames with little ash and no harmful substances, suitable for a reducing atmosphere. It yields good glaze color effects for white porcelain, blue-and-white porcelain, and colored glazes. The Zhen Kiln is the most completely preserved and valuable ancient porcelain kiln to date. On July 25, 2000, it was announced as a provincial-level key cultural relics protection unit by the Jiangxi Provincial People's Government.

3.7 Porcelain Music Waterside Pavilion

Performances using "Ci'ou," a new type of ethnic percussion instrument made primarily from porcelain plates. The Porcelain Music Ensemble first appeared at the '99 Kunming World Expo, causing a sensation. In 2000, after listening to the porcelain music, Comrade Qian Qichen, then Minister of Foreign Affairs, gladly inscribed "Marvelous Porcelain, Divine Charm." The Porcelain Music Ensemble has performed in over a dozen countries and regions including Japan and Russia, receiving warm welcomes wherever they go.

3.8 Small Ware Workshop

This workshop mainly produces small items, primarily daily-use porcelain, including bowls, cups, saucers, and plates. The products are known for their fine texture, regular shape, and are renowned for being as white as jade, as bright as a mirror, as thin as paper, and as resonant as a chime stone.

3.9 Porcelain-Making Workshop

The porcelain-making workshop, commonly known as "坯房" (clay room), is a workshop building for making porcelain bodies and underglaze painting on porcelain bodies. It exhibits clear characteristics of early capitalist萌芽 (sprouts), making the porcelain-making workshop building a rare existing example of ancient Chinese industrial architecture and physical evidence of the existence of capitalist萌芽 during China's Ming and Qing dynasties.

3.10 Ming Dynasty Residential Complex

The "Ming Residential Complex" consists of eight buildings including a gate, shops, ancestral halls, and residential houses. In December 1987, it was announced as a provincial-level key cultural relics protection unit by the Jiangxi Provincial People's Government.

3.11 Qing Garden

The "Qing Garden" contains four Qing Dynasty buildings: "Yuhua Hall," "Dafu Di," Cangxi Residential House, and the residence of a kiln wood merchant boss. The entire complex stands majestically with exquisite materials. In December 1987, it was announced as a provincial-level key cultural relics protection unit by the Jiangxi Provincial People's Government.

3.12 Tang Ying Memorial Hall

Tang Ying (1682-1756) was from Fengtian (present-day Shenyang, Liaoning) during the Qing Dynasty, belonging to the Han Army White Banner. His courtesy name was Jungong, and he styled himself the "Snail-Dwelling Old Man." Starting from the sixth year of the Yongzheng reign (1728), he was stationed at the Jingdezhen Imperial Kiln as an assistant official. From the first year of the Qianlong reign (1736), he successively managed the Huaian Customs and Jiujiang Customs while also overseeing kiln affairs until the twenty-first year, managing the Jingdezhen Imperial Kiln for over twenty years in total. He dedicated himself to the study of porcelain-making techniques, achieving great success in both imitation of antiques and innovation. The porcelain he supervised is called "Tang Kiln" porcelain. His works "Taocheng Jishi" (Record of Ceramic Achievements), "Taoye Tushuo" (Illustrated Description of Pottery and Kiln Firing), and "Taoren Xinyu" (Words from a Potter's Heart) are all important documents for studying the history of Jingdezhen porcelain making. To commemorate this predecessor and inherit and develop the excellent culture of the Chinese nation, the "Tang Ying Memorial Hall" was specially established.

3.13 Temple of the Wind and Fire Immortal Master

The building of the Temple of the Wind and Fire Immortal Master was constructed during the Jiaqing period of the Qing Dynasty (1796-1820). The building is divided into a front hall and a rear resting area, covering an area of 485 square meters. In January 1989, this building was announced as a key cultural relics protection unit of Jingdezhen City.

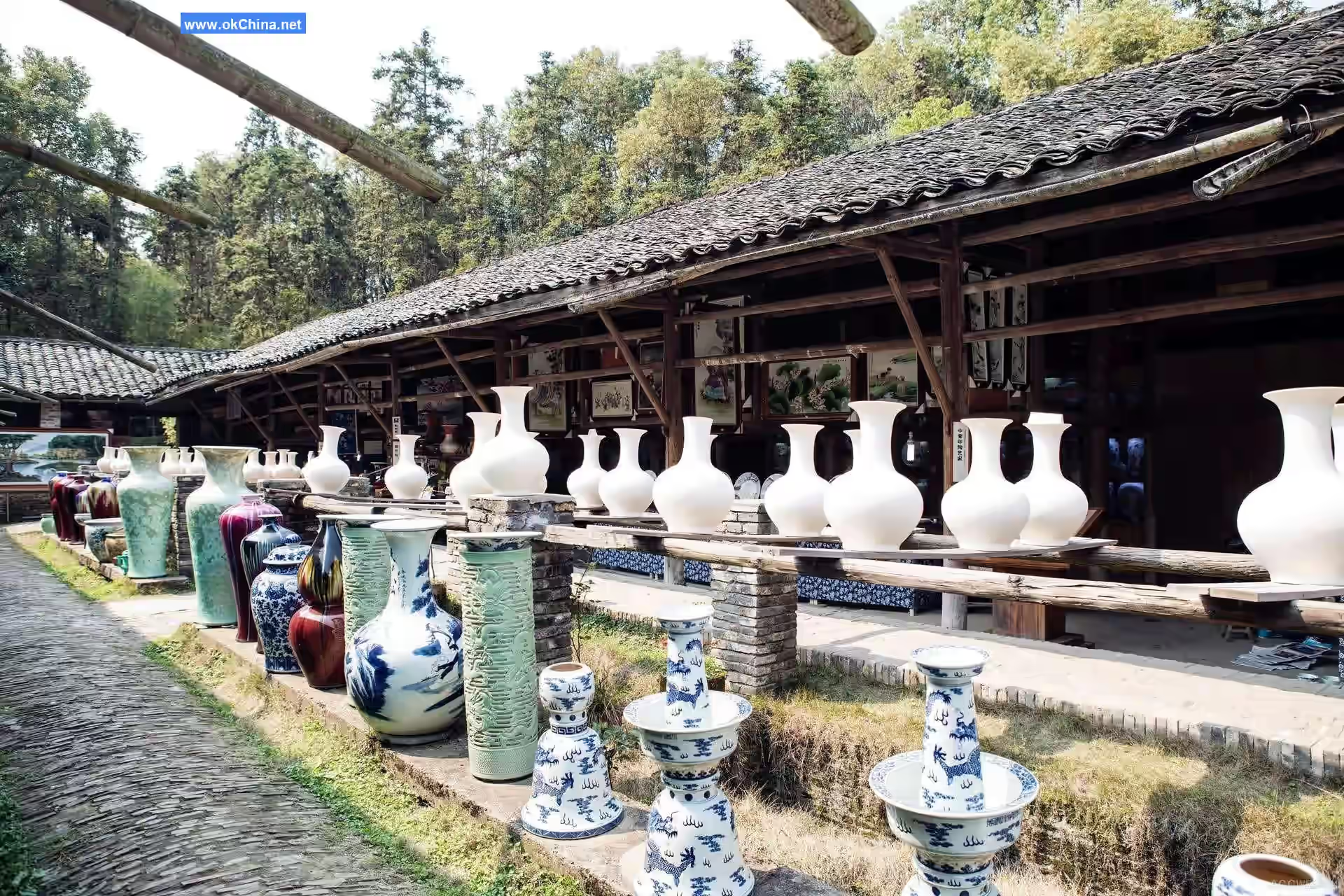

3.14 Large Ware Workshop

This workshop mainly produces large decorative porcelain such as large plates, large vases, and large jars. The production of its products is difficult and requires high technical skill.

4. Scenic Area Activities

4.1 Jingdezhen International Ceramics Festival

The Jingdezhen International Ceramics Festival is held in Jingdezhen every year in mid-October. During the festival, activities such as trade negotiations and exhibitions of fine porcelain are held.

4.2 Ancient Kiln Re-firing

At 15:18 on March 18, 2015, the Ming Dynasty Gourd Kiln in the Ancient Kiln Folk Customs Expo Area was ignited for firing, marking the first firing of the ancient kiln in 2015. Starting from March 2015, the ancient kiln has been regularly fired every month. Visitors to the ancient kiln will have more opportunities to watch wood-fired porcelain making and can witness the grand occasion of kiln opening and porcelain unloading on weekends. By the end of 2015, the Qing Dynasty Zhen Kiln, Ming Dynasty Gourd Kiln, Yuan Dynasty Mantou Kiln, Song Dynasty Dragon Kiln, and the Qing Kiln, Dragon Jar Kiln, and Wind and Fire Kiln from the Ming and Qing Imperial Kilns had all been successfully re-fired.

4.3 Porcelain Expo

On October 11, 2015, a Porcelain Expo was held at the Jingdezhen Ancient Kiln Folk Customs Expo Area. This expo included three events. First, at 09:00 in the morning, the Bronze Statue of Kiln God Tong Bin was consecrated to bless potters for generations. Second, at 10:38, the Zhimeixuan Ceramic Exhibition Hall was opened, unveiling a treasure trove of knowledge. Third, at 11:18, the Ming and Qing Imperial Wind and Fire Kiln was opened, displaying treasures and passing on the thousand-year-old kiln fire.

4.4 Porcelain Music Performances

The scenic area hosts daily performances by the "Porcelain Music Waterside Pavilion" Porcelain Music Ensemble. Monday to Friday (six performances): 9:30–9:50, 10:20–10:40, 11:10–11:30, 14:00–14:20, 14:50–15:10, 15:40–16:00. Saturday to Sunday (four performances): 9:30–9:50, 10:20–10:40, 11:10–11:30, 14:00–14:20.## 5. Porcelain Culture

5.1 Overview

The English name "China" for porcelain is actually a pun, referring to both the country "China" and "porcelain," reflecting the Western world's admiration for Chinese porcelain and their perception of Chinese culture. China is the birthplace of porcelain. As early as the Eastern Han Dynasty, mature celadon was successfully fired. Porcelain from the Tang and Song Dynasties reached an exceptionally high artistic level and was exported in large quantities worldwide via the Silk Road. Jingdezhen, a representative porcelain-producing region in China, is renowned as the "Porcelain Capital." Since the Tang Dynasty, its porcelain-making techniques have continuously evolved. Particularly during the Song Dynasty, Jingdezhen's Qingbai porcelain (Yingqing porcelain) became famous for its fine texture and unique glaze color. In the Yuan Dynasty, Jingdezhen's blue-and-white porcelain became a mainstream export product, reaching as far as the Middle East and Europe. During the Ming and Qing Dynasties, Jingdezhen's porcelain-making techniques saw further innovation. Exquisite porcelains like Wucai (five-color) and Fencai (familie-rose) were produced in large quantities, becoming a primary source of imperial porcelain. They were extensively exported worldwide via the Maritime Silk Road, serving as a crucial medium for cultural exchange between China and other nations. After the 16th century, with the opening of new sea routes, Chinese porcelain began entering Europe in large quantities, becoming coveted luxury items among European nobility and wealthy merchants. Due to its widespread dissemination and high praise in Europe, Europeans gradually used "China" to refer to the country and as the name for porcelain, embodying Western admiration for Chinese porcelain and highlighting its significant position in world cultural history.

5.1.1 Introduction to Porcelain

Among Jingdezhen's porcelains, the most famous include the elegant and understated blue-and-white porcelain; the clear and translucent blue-and-white "Linglong" (exquisite) porcelain; the multicolored colored glaze porcelain; the serene and refined blue-and-white Yingqing porcelain; the simple and graceful Gucai (ancient colored) porcelain; the vibrant and colorful Xincai (new colored) porcelain; the bright and elegant Yaocai (kiln colored) porcelain; and the innovative integrated decorative porcelain. These precious and renowned porcelains are hailed as "the essence of the Chinese national culture" and "treasures of the porcelain nation."

5.1.2 Variety Classification

Linglong Porcelain

Jingdezhen blue-and-white Linglong porcelain was created and developed during the Ming Dynasty's Yongle period (1403-1424) based on openwork techniques, boasting a history of over 500 years. Artisans use blades to carve numerous rice-grain-like holes into the unfired body, known as "Mi Tong" or "Linglong eyes." These are then filled with translucent glaze material, combined with blue-and-white decoration, and fired in the kiln. The result is a porcelain that appears clever, clear, and translucent, exceptionally elegant and pristine.

Blue-and-White Porcelain

Jingdezhen blue-and-white porcelain is acclaimed as a "treasure among mankind." It originated in the Yuan Dynasty and peaked during the Ming and Qing Dynasties. Cobalt oxide pigment is used to paint patterns on the unfired body, which is then glazed and fired once at high temperature. It features an interplay of blue and white, pleasing and interesting, crystal clear and bright, beautiful and enduring.

Fencai (Familie-Rose) Porcelain

Fencai, also known as soft colors, is an overglaze decoration for porcelain. It began in the late Kangxi period of the Qing Dynasty and was perfected during the Yongzheng and Qianlong reigns. The method involves outlining the pattern on a white porcelain body, then filling in with colored pigments, and firing at temperatures above 700 degrees Celsius. The colors are soft, the painting delicate and neat, possessing both the flavor of traditional Chinese painting and a sense of relief. The designs are rich in national characteristics, featuring figures from Chinese historical stories and myths, beautiful and colorful landscapes, lifelike birds and feathers, and neat, symmetrical geometric patterns.

Colored Glaze Porcelain

Colored glaze porcelain relies on changes in glaze color to decorate the ware. Typically, adjusting the content of various trace elements in the glaze material can alter the glaze color, such as copper red, cobalt blue, iron black, lead green, etc. Adding certain metallic oxides to the glaze material results in specific inherent colors after firing. The primary factors affecting the coloration are the metal oxides acting as colorants. Additionally, the composition of the glaze, particle size, firing temperature, and kiln atmosphere are closely related.

Thin-bodied Porcelain

Thin-bodied porcelain, also known as "slip-cast porcelain" or "eggshell porcelain," is one of the long-renowned special craft products among Jingdezhen's famous traditional porcelain varieties. Its characteristics include a body as thin as an eggshell, translucent, made purely from glaze material. Production involves dozens of steps from ingredient preparation, throwing, trimming (refining the body), glazing, painting, to firing, all done by hand and requiring three separate firings. The trimming and artistic processing are particularly meticulous. Trimming undergoes repeated carving through rough, fine, and precise stages, reducing a 2-3 mm thick rough body to about 0.5 mm. The body thickness is mostly within 1 mm, described as "thin as a cicada's wing, light as a floating cloud." It is lightweight, elegant, exquisitely crafted, with good light transmission, and is one of Jingdezhen's traditional artistic porcelain varieties.

Sculptural Porcelain

Jingdezhen porcelain sculpture production can be traced back over 1,400 years, with large animal figures like "lions" and "elephants" made as early as the Sui Dynasty. Contemporary Jingdezhen boasts exquisite porcelain sculpture craftsmanship with a complete range of techniques, including full-round sculpture, pinching sculpture, openwork carving, and relief carving. The products are diverse, featuring Buddha statues and deities, flowers, plants, fish, insects, pavilions, towers, animal toys, etc. The forms are beautiful, combining shape and spirit, varied and lifelike. Decoration is rich, including high-temperature colored glazes and underglaze Wucai. The artistic expression is strong, ranging from solemn and robust, elegant and fresh, to magnificent and dazzling.

Blue-and-White Yingqing Porcelain

Blue-and-white Yingqing porcelain refers to ware with both serene and elegant "blue-and-white" painting and lightly carved, delicate patterns on the same Yingqing glazed body. This is a new variety created by Jingdezhen in 1983. The glaze color resembles white jade, the patterns are crystal clear, and the underglaze designs merge with the blue-and-white, making the ware appear more elegant and refined. On March 16, 1984, at a technical appraisal meeting convened by relevant departments, ceramic experts recognized the product as "innovative, possessing unique artistic effects, a new high-end product representing an upgrade, and a domestic pioneer."

5.2 Historical Origins

5.2.1 Origin of the Name

Jingdezhen has long been known as the "Porcelain Capital." Here, kiln fires have burned continuously for a millennium, and its porcelain is renowned worldwide for its unique style described as "white as jade, bright as a mirror, thin as paper, and resonant as a chime stone." The primary areas for Jingdezhen's handmade porcelain craftsmanship are various urban and rural locations within Jingdezhen City (Xinchang; Laochang; Fanjiajing; Sanlumiao; High-tech Zone, etc.). Jingdezhen has a long history of porcelain making. It became particularly famous during the Song Dynasty for the fine texture and unique glaze of its Qingbai (Yingqing) porcelain. It was selected by the imperial court as the site for an official kiln and named "Jingdezhen." In the Yuan Dynasty, Jingdezhen's blue-and-white porcelain technology achieved major breakthroughs, becoming a mainstream export product sold as far as the Middle East and Europe. During the Ming and Qing Dynasties, Jingdezhen's porcelain-making techniques further innovated. Exquisite porcelains like Wucai and Fencai were produced in large quantities, becoming a primary source of imperial porcelain. They were extensively exported worldwide via the Maritime Silk Road, serving as a crucial medium for cultural exchange between China and other nations. For over a thousand years, Jingdezhen's porcelain industry has synthesized the achievements of famous kilns from all dynasties and gathered the essence of techniques from various regions, forming a unique handmade porcelain production system and creating the most glorious and splendid chapter in Chinese ceramic history. Its achievements, influence, exquisite craftsmanship, and comprehensive variety are unmatched by any other kiln site in any era. Its porcelain-making techniques are listed as a National Intangible Cultural Heritage, and its ancient kiln sites are designated as a World Cultural Heritage, further solidifying its status as the "Porcelain Capital."

5.2.2 Founder

Zhao Kai (304 AD — ?), courtesy name Shupeng, was a native of Fuyang, Hebei (present-day Ci County, Handan City, Hebei Province). He was a potter of the Jin Dynasty and the ancestral master of Jingdezhen porcelain. Early in his career, he served as an official in Fujian, Zhejiang, and Jiangxi. Due to his refusal to curry favor, his hatred of evil, and offending superiors and colleagues, he fell victim to treacherous officials, was demoted, and retired to Xinping Town (predecessor of Jingdezhen). While serving in Zhejiang, he learned and mastered the porcelain-making techniques of the Yue Kiln. He implemented a series of major reforms in the body and glaze preparation, shaping, and firing processes of Xinping Town's ceramics, significantly improving local technical levels and product quality. He played an important role in advancing Xinping Town's production from earthenware to porcelain, earning respect and admiration from later generations, who called him the "Master of Porcelain Making." According to the "Fuliang County Annals," "His ways were mysteriously effective, his methods benefited living beings... Most townspeople were potters, all relying on divine protection." During the Ming Dynasty's Hongxi period (1425), the junior eunuch Zhang Shan began worshipping the deity protecting pottery. He built a "Master Temple" within the town's imperial porcelain factory, later also called the "Protecting Pottery Divine Shrine," honoring Zhao Kai as the "Master" and "Deity Protecting Pottery." Ming Dynasty scholar Zhan Shan wrote the "Record of the Master Temple."

5.2.3 History of Porcelain Making

Jingdezhen porcelain boasts over 2,000 years of pottery-making history, over 1,000 years of official kiln history, over 600 years of imperial kiln history, and over 70 years of ceramic production history since the founding of New China.

Before the Song Dynasty

The earliest recorded figure in Jingdezhen's early porcelain making is from the Eastern Jin Dynasty—Zhao Kai, an official of that period who was later revered by Jingdezhen potters as the ancestral master of ceramics. A more mature period of ceramic production in Jingdezhen began in the Tang Dynasty. Porcelain products from this time were already very exquisite, praised as "imitation jade ware." According to the Qing Dynasty "Fuliang County Annals": "In the fourth year of Wude (621 AD), a potter named Tao Yu transported porcelain to the Guanzhong region, called it imitation jade ware, and presented it to the imperial court. Thereupon, an edict ordered Zhong Chu and others, along with Yu, to make vessels for imperial use." This shows that during the Tang Dynasty, Jingdezhen's ceramic craftsmanship had already reached a high technical level, but the true prosperity in quality and scale began in the Song Dynasty.

Song DynastyStarting from the Song Dynasty, Jingdezhen became a significant production base for porcelain. During the Jingde era of the Northern Song Dynasty (1004–1007), Emperor Zhenzong bestowed his reign title "Jingde" upon this porcelain-producing region and mandated that the phrase "Made in the Jingde Era" be inscribed on the bottom of all porcelain products as a hallmark. From then on, Jingdezhen became inextricably linked with Chinese porcelain.

The Song Dynasty marked a glorious period for Jingdezhen's ceramic production. Nationwide porcelain manufacturing flourished, and the celadon and white porcelain produced during this time held high artistic and historical value. This era also marked the historical starting point of Jingdezhen as an important and renowned porcelain-producing center in China. Meanwhile, shadow-blue porcelain, an innovative variety based on the techniques of bluish-white porcelain, became the highlight of Song Dynasty ceramics. Successfully fired during the mid-Northern Song Dynasty and produced on a large scale during the Southern Song Dynasty, it had a profound and lasting impact on later generations.

The discovery of bluish-white porcelain artifacts from the Song Dynasty at the Hutian Kiln site in the southern suburbs of Jingdezhen (now the Jingdezhen Hutian Ancient Kiln Site Museum) demonstrates that Jingdezhen's porcelain-making techniques had already reached a mature level during the Song Dynasty. The Song Dynasty merchant ship "Nanhai No. 1," salvaged from the waters off Guangdong Province, China, in 2007, was found to be carrying Jingdezhen bluish-white porcelain, indicating that Jingdezhen's porcelain was already being exported via maritime trade during the Song Dynasty.

Bluish-white porcelain and shadow-blue porcelain are fundamentally similar, with slight differences: bluish-white porcelain emphasizes the body, which is pure white and highly lustrous, while shadow-blue porcelain emphasizes the glaze, which is thick, transparent, and shiny.

Yuan Dynasty

During the Yuan Dynasty, Jingdezhen's porcelain-making techniques advanced unprecedentedly compared to the Song Dynasty, making it the kiln site with the highest porcelain-making skills in the country at the time. The "Fuliang Porcelain Bureau" was established to oversee the town's ceramic production.

The Yuan Dynasty had the most extensive territory in Chinese history, which unprecedentedly expanded the sales range of Jingdezhen porcelain and significantly increased its sales volume compared to the previous Song Dynasty.

The primary decorative styles of Jingdezhen porcelain during the Yuan Dynasty were blue-and-white and underglaze red, with "Yuan blue-and-white" (as Yuan Dynasty blue-and-white porcelain is commonly referred to in the cultural relics and antique collection circles) being the most famous. Yuan Dynasty blue-and-white porcelain was mainly characterized by large vessels, including large plates, jars, gourd-shaped bottles, plum vases, and stem bowls. These blue-and-white ceramics had a profound influence on later generations, and surviving or excavated pieces are extremely precious, with some varieties described as "priceless."

According to media reports, on July 12, 2005, a Yuan Dynasty blue-and-white porcelain jar-shaped vessel titled "Ghost Valley Descending the Mountain," produced in Jingdezhen, was auctioned in London, UK, fetching a record-breaking price of 230 million RMB, setting a historical record for the auction price of ceramic products worldwide. Experts believe that Yuan Dynasty blue-and-white porcelain holds an unshakable dominant position in the history of Chinese ceramics, representing the pinnacle of the development of Chinese blue-and-white porcelain.

The Yuan Dynasty is a distant era, and people at the time had little awareness of preserving cultural relics, so very few Yuan blue-and-white pieces have survived, making them extremely precious. As the Mongols valued white as a symbol of beauty, blue-and-white porcelain was not highly regarded by them; instead, white porcelain was more popular during the Yuan Dynasty.

Ming Dynasty

During the Ming and Qing Dynasties, Jingdezhen's ceramic production became more refined, serving as an important production base for imperial court porcelain.

The Ming Dynasty marked the beginning of a prosperous era for Jingdezhen porcelain production. Porcelain-making techniques and varieties became more advanced and diverse than in previous dynasties. The Jingdezhen Imperial Kiln Factory, established during the Ming Dynasty, was dedicated to producing porcelain for the imperial court.

The blue-and-white porcelain of the Yongle and Xuande reigns, the doucai porcelain of the Chenghua reign, and the wucai porcelain of the Jiajing and Wanli reigns are among the finest examples of Ming Dynasty ceramics. Zheng He of the Ming Dynasty exported large quantities of Jingdezhen porcelain overseas, which had a significant impact on Jingdezhen porcelain at the time and in later periods.

Qing Dynasty

Jingdezhen porcelain during the Qing Dynasty can be considered the pinnacle of ancient Chinese ceramic development. The Qing court appointed specialized overseers to supervise porcelain production in Jingdezhen. The establishment of this overseer system elevated Jingdezhen porcelain to an almost unparalleled level of excellence.

During this period, in addition to the official kilns producing porcelain for the court, the number of private kilns in Jingdezhen also reached an unprecedented peak.

Early Qing Dynasty blue-and-white porcelain is considered a treasure in contemporary collecting circles, while Qing Dynasty famille rose porcelain is a rare masterpiece in ceramic collecting, with its value even rivaling that of Yuan blue-and-white porcelain. Cloisonné, which combined Chinese and Western techniques, also gained great fame.

According to the Qing Dynasty "Jingdezhen Tao Lu" (Records of Jingdezhen Ceramics): "The vessels are exquisite, the craftsmanship is superb, the colors are perfect, imitating ancient methods while innovating, with patterns and styles changing monthly and yearly. The imperial kiln supervision, in particular, surpassed all previous eras." This sufficiently illustrates the extraordinary achievements of Jingdezhen porcelain production at the time.

Qing Dynasty ceramics can be said to be unprecedented. The Qing emperors placed great emphasis on ceramics, cultivating a group of highly artistic overseers and national-level painters specifically for producing exquisite porcelain.

Republic of China Era

During the Republic of China era, prolonged warfare and social instability severely hindered Jingdezhen's ceramic production. However, ceramic techniques and production management continued to advance under difficult circumstances. Despite the instability, some outstanding ceramic talents emerged, such as the famous "Eight Friends of Zhushan" in Jingdezhen. Overall, however, the entire ceramic industry was ultimately constrained by the effects of war and remained stagnant.

People's Republic of China

With over 2,000 years of porcelain-making history, Jingdezhen has thrived and prospered because of porcelain. From the first year of the Jingde era in the Northern Song Dynasty to the Qing Dynasty, Jingdezhen produced porcelain for the imperial court for over 900 years.

Dr. Joseph Needham of the United Kingdom stated, "Jingdezhen is the world's earliest industrial city. Before the Western Industrial Revolution, Jingdezhen porcelain had already become a global industry."

After the founding of New China, Jingdezhen porcelain achieved unprecedented development. Following the establishment of the People's Republic of China in 1949, the ceramic industry, as the leading industry of Jingdezhen, made significant strides. In 1950, the state-owned Jingdezhen Jianguo Porcelain Company was established and began porcelain production. Existing ceramic enterprises underwent socialist transformation, achieving cooperation and public-private partnerships. During the planned economy era, Jingdezhen porcelain, with its ten major porcelain factories, leveraged the strength of leading enterprises such as Jingdezhen Porcelain Factory, Jiangxi's largest industrial ceramic enterprise Jingdezhen Electrical Porcelain and Appliance Company, and several ministry- and province-affiliated electronic ceramic enterprises. Jingdezhen porcelain flourished in daily-use ceramics, art ceramics, industrial ceramics, architectural ceramics, and electronic ceramics, forming scale advantages and brand benefits. Whether in domestic or international markets, Jingdezhen adopted a "large and comprehensive" production structure for ceramics. In the late 1980s and early 1990s, Jingdezhen, with only 3% of Jiangxi Province's population, contributed 20% of the province's tax revenue, becoming an important industrial base in Jiangxi.

In the early 1990s, as the planned economy gradually transitioned to a market economy, the traditional ceramic industry experienced severe "adaptation issues," plunging the entire sector into difficulties. The ten major porcelain factories embarked on a challenging reform path, but progress remained slow.

In 2007, the State Council of China issued the "Several Opinions on Promoting the Sustainable Development of Resource-Based Cities," providing strong policy support for the transformation and development of resource-based cities. Jingdezhen successfully applied to become a pilot city for national resource-based city transformation policies, setting it on a new path of transformative development.

In 2012, the total output value of Jingdezhen's ceramic industry exceeded 20 billion RMB for the first time. The city had over 5,000 ceramic enterprises, including nearly 100 large-scale ceramic enterprises, with more than 100,000 people employed in ceramic production, sales, and supporting industries. The Jingdezhen High-Tech Zone Ceramic Industrial Park alone housed over 70 ceramic enterprises, with an annual output value of nearly 4 billion RMB. The number of registered ceramic trademarks in the city increased from less than 50 in 2008 to over 380 in 2012, including 1 nationally renowned trademark, 2 nationally recognized brand products, 23 Jiangxi Province famous trademarks, 8 Jiangxi brand products, 23 municipal well-known trademarks, and 139 registered ceramic trademarks. The city also had 7 national and provincial-level cultural industry demonstration bases and nearly 5,000 creative entities. It was home to dozens of national-level masters and over 8,000 provincial and municipal senior craft artists and folk ceramic artisans.

In 2014, the total output value of Jingdezhen's ceramic industry reached 29.16 billion RMB, ranking fifth among China's top ten ceramic production regions and accounting for 20.05% of the city's total industrial output value.

In 2016, the total output value of Jingdezhen's ceramic industry grew from 4.2 billion RMB in 2007 to 36.67 billion RMB.

In 2017, the total output value of Jingdezhen's ceramic industry was 37.2 billion RMB.

In 2021, the total output value of Jingdezhen's ceramic industry was approximately 51.62 billion RMB, with art and decorative ceramics accounting for 18.53 billion RMB.### 5.3 Memory of Porcelain Making

5.3.1 Handmade Porcelain Craft

The state places great importance on the protection of intangible cultural heritage. On May 20, 2006, the Jingdezhen handmade porcelain craft was approved by the State Council to be included in the first batch of national-level intangible cultural heritage list.

The Jingdezhen handmade porcelain craft is characterized by a high degree of specialization and extremely detailed division of labor. Its core processes include throwing, trimming, painting, glazing, and firing.

- Throwing: Also known as "forming," it is the initial stage of shaping and the creation of the prototype of the vessel. It involves placing prepared clay on a potter's wheel and using wheel-throwing techniques to form a坯件 (greenware) of a specific shape and size.

- Trimming: Also called "refining the坯." It involves旋削 (rotary cutting) the rough, uneven, and irregular坯件 after the印坯 (molding) process twice to achieve appropriate thickness and consistency inside and out.

- Glazing: Commonly known as "applying the glaze." It involves coating the interior and exterior of the坯件 with a vitreous glaze to make it smooth and lustrous. Methods include dipping, pouring, blowing, swirling, and brushing.

- Painting with Cobalt Blue: Commonly known as "painting the坯." It involves painting designs on the坯胎 (unglazed body) with cobalt blue pigment, drawing blue borders or writing blue characters, followed by glazing and firing.

- Firing: This is the final crucial step in porcelain making. It involves placing saggars containing the finished坯件 on the kiln bed according to their kiln positions, firing them with pine wood or槎柴 (a type of firewood) to 1270–1300 degrees Celsius, using a method that starts with an oxidizing flame and then switches to a reducing flame. The process is divided into three stages:溜火 (slow heating),紧火 (intense heating), and净火 (cleansing fire), taking a full day and night (24 hours) to transform the坯胎 inside the saggars into porcelain.

The important forming processes in Jingdezhen's handmade porcelain craft were初步建立 (initially established) during the Song Dynasty. The division of labor within the porcelain industry became increasingly refined, commonly employing techniques such as throwing,印坯, trimming,修足 (foot trimming),蘸釉 (dip glazing), and荡釉 (swirl glazing) to make porcelain坯. Firing techniques included saggar stacking仰烧 (upright firing),垫钵覆烧 (firing with垫钵 and覆烧), and支圈覆烧 (firing with支圈 and覆烧). By the Yuan Dynasty, the "binary配方 method" of mixing porcelain stone with kaolin and the underglaze blue-and-white painting technique were invented. During the Ming and Qing dynasties, Jingdezhen's porcelain industry developed further. "It takes the effort of seventy-two pairs of hands to complete a single piece of porcelain, with countless细微节目 (minute details) still not fully accounted for." The system of handmade porcelain craftsmanship was essentially perfected, with mining and each process simplified to the utmost degree. Those who炼泥 (refined clay) only炼泥, those who threw only threw, and painters only painted without染色 (coloring), while染者 only染色 without painting. Such明细分工 (detailed division of labor) improved efficiency, and there were skilled artisans with exceptional expertise in all aspects. Jingdezhen's handmade porcelain industry thus reached its historical peak.

Jingdezhen's handmade porcelain craft formed its own distinctive characteristics and system by integrating techniques from famous kilns across the country. The细度 (fineness) of its division of labor and the高度 (height) of its specialization are unmatched by other handicraft industries. Taking the Imperial Kiln Factory as an example, its production organization and division of labor were quite完备 (complete), encompassing various workshops for the坯-making industry: workshops for舂碓陶土 (pounding and preparing clay), workshops for making坯胎 of large and small圆器 (round ware) and琢器 (carved ware), workshops for making saggars, and various auxiliary workshops such as泥水作 (masonry),大木作 (carpentry for large structures),船木作 (ship carpentry), and铁作 (ironworking). Many specific operations were performed by highly specialized artisans.同时 (At the same time), both the firing and making processes were集中 (concentrated) within the factory, with several imperial kilns set up, forming a large-scale手工作坊 (handicraft workshop) that was门类齐全 (comprehensive in categories) and无所不及 (all-encompassing).

After "synthesizing the best," Jingdezhen disseminated its exquisite porcelain-making techniques, promoting the蓬勃 development (vigorous development) of the porcelain industry in全国 (the whole country) and worldwide porcelain-producing regions. Therefore, Jingdezhen's handmade porcelain craft and production system are truly outstanding representatives of China's ceramic industry. They embody the萌芽 (sprouts) of Chinese capitalism, are an important component of the traditional culture of the Chinese nation, and also serve as a vital link for economic and cultural exchanges between China and various ethnic groups in the East and West. In the 1980s, to配合 (coordinate with) urban renovation and protect a number of historical and cultural relics, the local government relocated and集中保护 (centrally protected) some of the ancient kiln sites, ancient workshops, and ancient buildings scattered throughout the urban area, establishing the Jingdezhen Ceramic Historical Exposition Area. The entire exposition area consists of two main scenic areas: the Ancient Kiln and the Ceramic History Museum. It is one of Jingdezhen's most important ceramic cultural tourism areas and has been called a "living ceramic museum" by domestic and international experts and ceramic enthusiasts.

5.3.2 Workshop Construction

In 2006, the State Council announced the construction techniques of Jingdezhen's traditional porcelain kilns as a national-level intangible cultural heritage. Restoring the Zhen Kiln is a direct protection of this national intangible cultural heritage.

The砌筑营造 (masonry construction) and修补 (repair) of porcelain kilns in Jingdezhen's porcelain industry are commonly referred to as "挛窑 (luán yáo)," a specialized skill. From the Yuan Dynasty onward, the挛窑 trade was世传经营 (handed down and managed) by the本地 (local) Wei family. By the Jiaqing period of the Qing Dynasty, the craft was learned by the Yu family from Duchang, Jiangxi, and passed down from them. Records indicate that in the late Qing Dynasty, there were over 100 Zhen Kilns in Jingdezhen, giving an idea of the兴盛 (prosperity) of the kiln industry.

The型制体量 (form and scale),结构比例 (structural proportions),砌筑材料 (masonry materials), and手工技法 (manual techniques) of the Zhen Kiln窑炉 (kiln) all have specific讲究 (particularities). They represent the highest technological level of traditional porcelain kiln construction techniques in the world and are the结晶 (crystallization) of centuries of labor experience and高度智慧 (high wisdom) of Jingdezhen's kiln workers. The砌筑 (masonry construction) of this Zhen Kiln窑炉 is the practical application of a national treasure-level traditional skill.

People in the Qing Dynasty described the挛窑 skill as follows: "I have seen them砌砖 (lay bricks). With one hand arranging and粘砌 (adhering and laying) the bricks, each brick is tested only three times before it is tightly粘住不动 (adhered and immovable). When applying the泥 (clay mortar), they合舀一拱泥 (scoop a拱 of泥 with both hands) and向排砌一层砖中间两分之 (split it in the middle of a row of laid bricks), then the泥自靠结砌两路流至脚 (the泥 naturally flows down both sides of the砌体 to the base). The bricklayer then picks up bricks one by one to arrange and粘砌. The制泥 (prepared泥) is稠如塘浆 (thick like pond slurry), yet not the same as what泥水工 (masons) use."

挛窑 uses specially made kiln bricks and挛窑泥.

Kiln bricks are the main material for砌筑 (masonry construction) or修补 (repairing) porcelain kilns. Their general length, width, and thickness specifications are 24×9×3.5 (cm). There are also specially sized条子砖 (strip bricks) and烟囱砖 (chimney bricks), etc.

The raw material for brick-making is mountain soil with good粘性 (adhesiveness) and high耐火度 (refractoriness). It undergoes processes such as踩炼 (treading and refining),成型 (forming),晾晒 (drying), and烧炼 (firing) to finally become kiln bricks. In the past, brick坯 were generally fired into "响砖" in porcelain kilns, using专门的圆窑包 (special round kiln packages) for firing.

After a period of use, kilns need修补 (repair) or拆倒重新砌筑 (dismantled and rebuilt). Therefore, Jingdezhen has a large number of窑砖头 (kiln brick fragments) left from dismantling kilns. After high-temperature煅烧 (calcination), these窑砖头,夹杂着 (mixed with)火红色 (fiery red) and黑釉色 (black glaze) colors, are widely used for砌墙 (building walls) and铺路 (paving roads), giving the porcelain capital a unique characteristic风貌 (appearance).

挛窑泥 is取自于 (taken from)田泥 (field泥), i.e., the soil beneath the surface layer of paddy fields, as it contains no沙石杂质 (sand or stone impurities), is粘性 (adhesive), and耐高温 (heat-resistant). The田泥 is transported to the kiln site and needs to be晒干 (sun-dried) to facilitate the rapid dissolution of the泥块 (clay lumps) with water before练制泥料 (preparing the clay).田泥 mixed with water and经过踩练后 (after being trodden and refined) becomes the泥浆状的挛窑泥 (slurry-like挛窑泥).

The construction techniques of Jingdezhen's traditional porcelain kilns are a national-level intangible cultural heritage. The production techniques of kiln bricks and挛窑泥 are important components of it. Due to the重新修复 (re-restoration) of the Qing Dynasty Zhen Kiln, traditional skills such as the烧制 (firing) of traditional kiln bricks and the制作 (production) of挛窑泥 have also been "activated."

Comments

Post a Comment